Why Every Business Should Take Electrical Inspections Seriously

When you walk into a modern office, store, or warehouse, it’s easy to overlook the hum of electricity working silently in the background. The lights stay on, the computers keep running, and the machines don’t miss a beat. But behind that smooth operation is an intricate electrical system that, if ignored, can quickly turn into a safety hazard or a costly repair. This is where routine electrical inspections step in—not as an optional luxury, but as a fundamental part of keeping a commercial space safe, compliant, and efficient.

Unlike replacing a light bulb or plugging in a surge protector, electrical inspections go deeper. They’re about preventing fires before they start, spotting weaknesses before they cause downtime, and ensuring your building meets the latest codes. Businesses often realize the value only after something goes wrong, but by then the damage may already be expensive—or irreversible.

The Role of Professional Electrical Inspections

In the world of commercial properties, inspections aren’t just box-ticking exercises. They’re proactive safety checks that can make or break a business’s long-term stability. Think about it: a factory with outdated wiring might still function day-to-day, but one spark could halt production for weeks. A restaurant that overlooks its electrical load could face blackouts during dinner rushes, losing customers and revenue in a matter of hours.

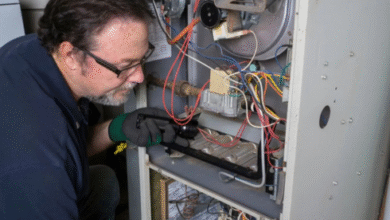

That’s why many companies turn to commercial electrical inspection services to help safeguard their operations. These professionals don’t just glance at wires; they analyze the system from top to bottom, looking at panel boards, breakers, wiring, outlets, and grounding methods. Their goal is to catch issues early—before they snowball into dangerous or financially draining situations.

Why Commercial Properties Are High-Risk

It’s not just about the size of a building. Commercial properties are high-risk because they often have higher electrical demands than residential spaces. Multiple air-conditioning units, industrial equipment, elevators, and endless computers mean heavier loads, which increases wear and tear on electrical systems.

Picture a busy office park. Each tenant plugs in printers, servers, and dozens of workstations. Over time, even a well-designed system can strain under that demand. Without regular inspections, those hidden weaknesses can result in blown fuses, overheating wires, or worse—a fire that shuts down the entire complex.

This is where the expertise of a commercial electrical inspector really shines. Unlike a general handyman or an employee who notices flickering lights, inspectors are trained to see the invisible problems: loose connections behind walls, circuits overloaded beyond capacity, or outdated installations that no longer meet code. Their trained eyes turn uncertainty into clarity, and for a business owner, that peace of mind is priceless.

Common Issues Found During Inspections

When businesses schedule inspections, the findings often surprise them. Some of the most common problems include:

- Overloaded circuits: Too many devices drawing power from a single circuit can create heat and stress.

- Improper grounding: Without proper grounding, even small electrical faults can damage equipment or shock workers.

- Outdated panels: Older systems may not handle the demands of modern technology, creating bottlenecks and risks.

- Damaged wiring: Insulation can wear down, especially in high-traffic or industrial environments.

- Non-compliance: Codes change over time, and what was acceptable 15 years ago may now be considered unsafe.

Each of these issues is like a ticking clock. The sooner they’re discovered, the easier—and cheaper—they are to fix. Left unchecked, they can escalate into emergencies that put employees, customers, and property in danger.

Safety, Savings, and Compliance

One of the biggest misconceptions is that inspections are just about following the law. Sure, regulations play a big role, and businesses are often legally required to maintain electrical safety standards. But the benefits go beyond compliance.

Regular inspections save money in the long run. By identifying inefficiencies, inspectors help reduce energy costs. For instance, a system struggling to meet demand may waste electricity, driving up monthly bills. Catching that early means adjustments can be made before costs spiral.

Then there’s the safety aspect. No business wants to face a lawsuit or reputation damage from preventable accidents. Employees need to know they’re working in a safe environment, and customers expect the same. A well-documented inspection history demonstrates due diligence—something insurance companies also appreciate when assessing liability.

Finding the Right Inspection Partner

Of course, not every electrician is equipped to handle commercial inspections. This is a specialized field, requiring knowledge of both heavy electrical loads and complex regulatory codes.

When searching for commercial electrical inspection near me, it’s worth doing a little homework. Look for companies that:

- Employ licensed inspectors with specific commercial experience.

- Offer detailed reports rather than vague summaries.

- Stay updated with the latest codes and safety practices.

- Provide clear recommendations, not just lists of problems.

A trustworthy inspection partner doesn’t just point out flaws; they guide you toward solutions. They should be able to explain technical findings in plain language and prioritize repairs based on urgency. That way, business owners can plan budgets and avoid last-minute surprises.

Real-World Impact

Let’s take an example. A mid-sized retail store recently brought in inspectors after noticing frequent tripping of breakers. The inspection revealed an outdated panel and improperly distributed load across circuits. The cost to fix it? Manageable. The cost if they hadn’t caught it? Potentially catastrophic, as overheated wires could have led to a fire during peak shopping hours.

Stories like this aren’t rare—they’re the quiet victories that inspections deliver every day. The disasters that don’t happen, the losses that never occur, the lives that remain safe—all because someone decided not to skip an inspection.

The Bottom Line

Electrical inspections may not be the flashiest part of running a business, but they’re one of the smartest investments a company can make. They protect people, safeguard property, and keep operations running smoothly. In a world where downtime can cost thousands per hour, and safety is non-negotiable, taking chances with electricity simply isn’t worth it.

So next time you walk into your office, warehouse, or shop and flip on the lights, remember the unseen system working tirelessly behind the scenes. Then ask yourself: when was the last time it was checked by a professional? If the answer is “I can’t remember,” it’s time to change that.