When the Walk-In Warms Up: A Real-World Look at Commercial Appliance and Refrigeration Repair

Running a business is a lot like juggling flaming swords—on a moving train—while trying not to spill your coffee. And if you’re in the food service, hospitality, or retail industry, then your appliances are part of your core team. They’re not just conveniences—they’re critical. So when the walk-in cooler starts creeping above safe temperatures or your commercial freezer starts sounding like it’s grinding gravel, that sinking feeling? Yeah, it’s real.

That’s when you find yourself googling “commercial refrigeration repair” or maybe “commercial appliance repair near me” at 7 a.m. on a Saturday, hoping someone answers the phone.

If that’s you—take a breath. Let’s talk about how these things go wrong, what to expect from a quality repair, and why ignoring a struggling machine isn’t saving money… it’s just borrowing trouble.

When the Fridge Stops, Everything Stops

In the world of business, time is money. But when your commercial fridge stops cooling? Now we’re talking product loss, health code violations, and unhappy customers. It’s not just time and money—it’s your reputation on the line.

Whether you’re running a cafe, a five-star kitchen, a grocery store, or a florist shop, your refrigeration units are doing 24/7 heavy lifting. They work hard, and most of the time, they do it without complaint—until they don’t.

Common Commercial Refrigeration & Appliance Issues

It doesn’t matter how fancy or rugged your equipment is, all machines wear down eventually. And with commercial appliances working harder and longer than residential units, things can break faster if they’re not maintained properly.

Here’s what usually goes sideways:

- Fluctuating temperatures – Could be failing thermostats, door seals, or coolant leaks.

- Loud or strange noises – Grinding, clicking, or buzzing? Could be a compressor or motor on its way out.

- Leaking water – Often a clogged drain line or defrost issue.

- Unit not powering on – Could be as simple as a tripped breaker… or a fried circuit board.

- Compressor problems – The heart of your system. When it goes, the whole machine feels it.

- Frost buildup – Bad defrost timers or broken fans can lead to ice where it shouldn’t be.

And it’s not just refrigeration units—think ovens, dishwashers, steamers, mixers, ice makers, and more. When even one piece of your setup fails, your whole operation slows down.

Can You Fix It Yourself?

It’s tempting, especially in a fast-paced environment, to try a quick DIY solution. Reset the breaker, clean the filters, check the door seal. Sure, some things are simple. And basic maintenance? Always a good idea.

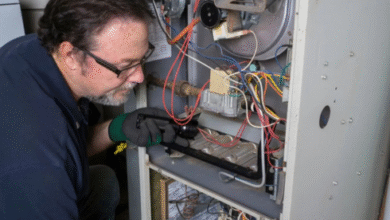

But beyond that? Commercial systems are complex, high-pressure, and high-voltage. Opening up a panel without proper training can not only void your warranty—it can be downright dangerous. And one wrong move could turn a repairable situation into a full replacement.

If you’re not trained, it’s best to step away from the toolbox and call in a professional.

What Makes a Great Commercial Repair Tech?

Here’s where it matters: not all repair technicians are equal. Fixing a home fridge is not the same as troubleshooting a 10-foot walk-in cooler or diagnosing a prep station on the fritz during lunch rush.

A good commercial appliance repair technician understands speed and accuracy are everything. You don’t just need the repair—you need the repair now.

Here’s what to look for:

- Specialized experience with commercial equipment – Not just residential knowledge.

- Fast response time – Especially for refrigeration emergencies.

- Brand familiarity – True pros know the quirks of Traulsen, True, Turbo Air, and more.

- Stocked parts vans – Because nobody wants to wait three days for a compressor relay.

- Clear communication – Diagnosing, quoting, explaining—no mystery tech speak.

- Emergency and after-hours availability – Because 3 a.m. freezer failures happen.

You want someone who sees your equipment not just as a machine—but as the lifeline of your business.

Repair or Replace?

It’s the question every business owner dreads.

Here’s the general rule of thumb:

- Repair if the unit is under 8–10 years old, the parts are available, and the issue is isolated.

- Replace if it’s older, has a history of problems, or the repair is more than 50% of replacement cost.

But there are intangibles too. If your fridge is a weird custom size, fits perfectly in your kitchen layout, or cost you an arm and a leg when it was new, repairing could still be worth it.

That’s where a trustworthy repair tech comes in—they’ll give you options, not just a sales pitch.

Preventive Maintenance: The Unsung Hero

If there’s one tip every repair expert agrees on, it’s this: preventive maintenance is gold. A regular service schedule—cleaning coils, checking refrigerant levels, inspecting electrical connections—can catch small problems before they become major ones.

Think of it like changing the oil in your car. It’s not exciting, but it’s what keeps everything moving smoothly.

And when you’ve got a business depending on uptime? That’s peace of mind you can’t put a price on.

Final Thought: When You Rely on Machines, Rely on the Right People

Running a business means juggling a hundred things at once. Equipment failure shouldn’t be one of them. Whether it’s a walk-in cooler, commercial oven, prep fridge, or fryer, when something breaks, you need fast, honest, expert help—and no surprises.

That’s where the pros come in. If you’re searching for commercial refrigeration repair, commercial appliance repair, commercial appliance repair, make sure you’re calling someone who truly understands how your business runs—and how much is riding on getting it right.

Because in the world of business, downtime isn’t just inconvenient—it’s expensive. And your reputation? That’s built one cold drink, one warm meal, and one happy customer at a time.